How air-entraining admixtures (AEA) play an important role for enhancing the durability of concrete?

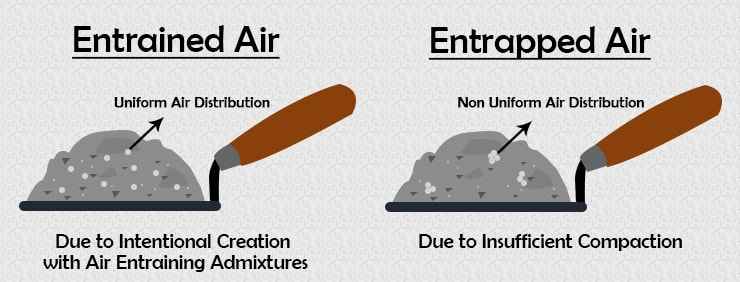

Concrete is a cornerstone of modern construction, offering strength and versatility. However, it faces challenges from environmental stresses, particularly in regions with extreme weather conditions. Air-entraining admixtures (AEAs) have emerged as essential additives for improving concrete's durability and performance. By introducing tiny air bubbles into the concrete mix, AEAs enhance its properties, making it more resilient against various challenges. Let’s explore how AEAs contribute to concrete durability, focusing on key aspects such as freeze-thaw resistance, workability, and long-term performance.

1. Improved Freeze-Thaw Resistance

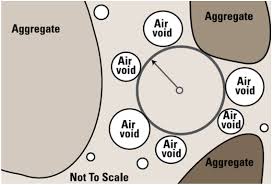

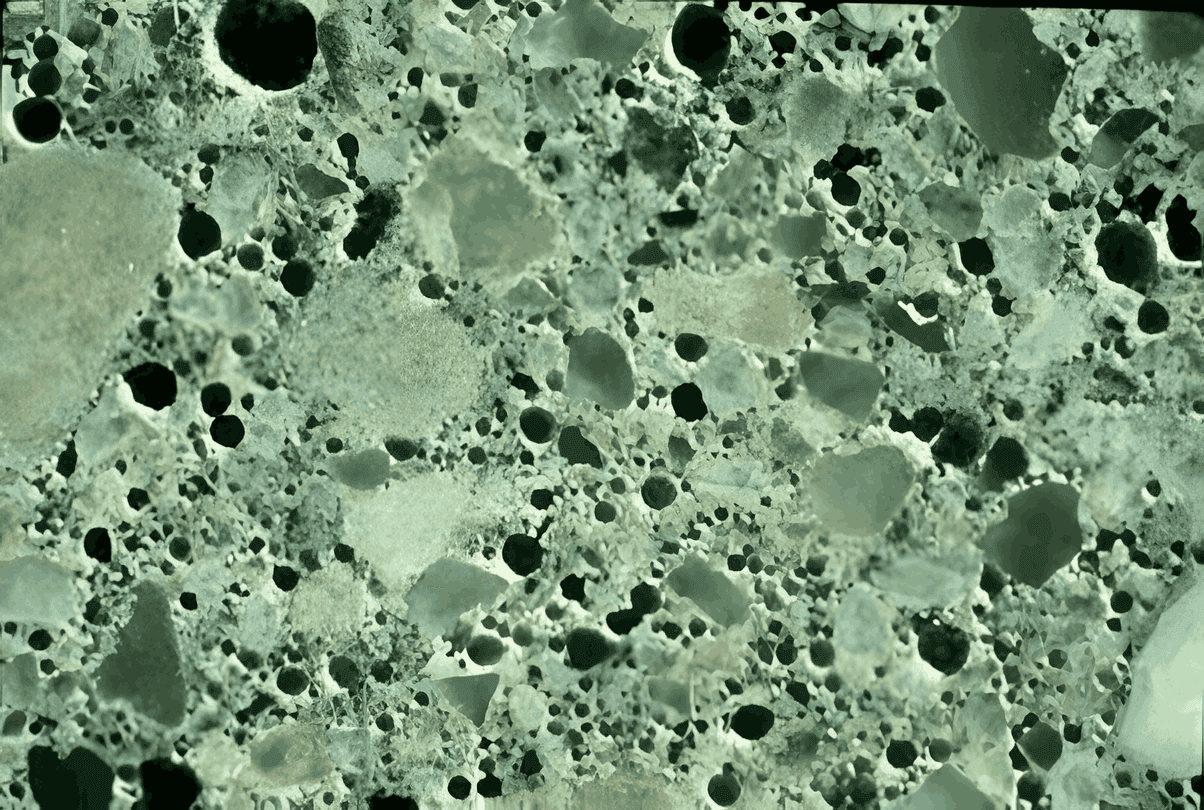

One of the primary benefits of AEAs is their ability to mitigate freeze-thaw damage. When water trapped in concrete pores freezes, it expands, exerting significant pressure on the surrounding structure. Repeated freeze-thaw cycles can cause cracking and scaling, compromising the concrete’s integrity. FCSC have AEA PLAST which is available in B2B that introduce microscopic air voids that act as relief chambers, allowing freezing water to expand without damaging the concrete. This mechanism is especially crucial in regions with harsh winters, ensuring the concrete retains its structural integrity for a longer period.

2. Enhanced Workability

The addition of AEAs improves the workability of concrete, making it easier to mix, place, and finish. The entrained air bubbles reduce friction within the mix, providing a smoother texture and better flow. This enhanced workability not only speeds up construction processes but also reduces labor costs. Furthermore, AEA PLAST of FCSC is being highly preferred to improve workability, ensuring uniform distribution of the mix, leading to a more consistent and durable final product.

3. Reduced Permeability

Concrete permeability plays a significant role in determining its lifespan. High permeability allows water, chemicals, and other harmful substances to penetrate the structure, leading to corrosion of reinforcement and weakening of the material. AEAs reduce the permeability of concrete by refining its microstructure. The air bubbles create a tighter matrix, minimizing the pathways for water and harmful substances to infiltrate. This reduction in permeability enhances the durability and longevity of concrete, especially in marine or industrial environments where exposure to aggressive agents is common.

4. Increased Resistance to Scaling

Scaling, often caused by de-icing chemicals or abrasive forces, can deteriorate the surface of concrete structures. AEA PLAST of FCSC helps combat this issue by reducing water absorption and providing a buffer against surface damage. The entrained air prevents moisture from accumulating near the surface, reducing the risk of scaling under freeze-thaw cycles. This characteristic is vital for pavements, driveways, and other exposed concrete surfaces.

5. Lower Risk of Cracking

Cracking is a common issue in concrete due to shrinkage, thermal stresses, and external loads. AEAs mitigate the risk of cracking by improving the flexibility of the material. The entrained air voids act as shock absorbers, dissipating stress concentrations that can lead to cracks. For example- FCSC produced AEA PLAST comes with flexibility and is particularly beneficial in applications where concrete is subjected to dynamic loads or temperature fluctuations.

6. Enhanced Flexibility

Concrete, though strong, is inherently brittle. AEAs enhance its flexibility, allowing it to withstand movements caused by thermal expansion, contraction, and external stresses. This added flexibility reduces the likelihood of failure in the form of cracks or structural deformation, making AEAs indispensable for large-scale infrastructure projects like bridges and highways.

7. Better Resistance to Chemical Attacks

Chemical attacks, such as sulfate exposure, chloride ingress, and acid rain, are significant threats to concrete durability. AEAs provide an additional layer of protection by minimizing permeability and preventing aggressive chemicals from reaching the reinforcement. Furthermore, the improved microstructure resists the breakdown of concrete under harsh chemical environments, ensuring its longevity in industrial and coastal settings.

8. Longer Service Life

All the above benefits culminate in a significantly extended service life for concrete structures treated with AEAs. At FCSC, our expert recommended AEA PLAST to address common durability challenges like freeze-thaw damage, scaling, cracking, and chemical attacks. AEAs reduce maintenance costs and increase the lifespan of concrete. For contractors and builders, this translates into higher cost efficiency and greater sustainability for their projects

Why Choose Firstchoice Specialty Chemicals?

At Firstchoice Specialty Chemicals (FCSC), we understand the critical role of air-entraining admixtures in modern construction. Our premium range of AEAs such as AEA PLAST, available in B2B channels, is engineered to meet the diverse needs of the construction industry, ensuring optimal performance and durability for every project. Whether you're working on roads, bridges, or residential buildings, our products are designed to deliver superior quality and reliability.

Conclusion : Air-entraining admixtures are not just additives; they are game-changers in concrete technology. By enhancing freeze-thaw resistance, workability, flexibility, and resistance to chemical attacks, AEAs significantly improve the durability and performance of concrete structures. With these advantages, AEAs pave the way for sustainable and long-lasting infrastructure. For construction professionals looking to build resilient structures, incorporating high-quality AEAs from Firstchoice Specialty Chemicals is a step toward excellence. Partner with us to ensure your concrete solutions stand the test of time.